rotary kiln working principlejayden ballard parents

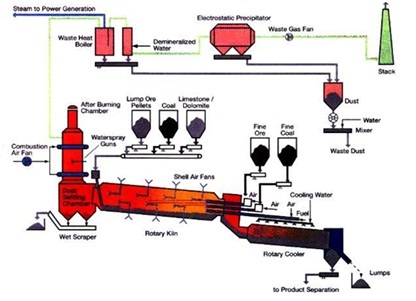

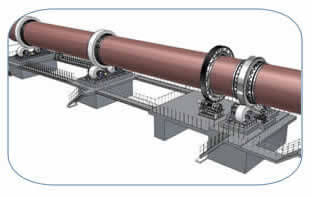

EPA [16] affirmed that the availability of land for constructing new landfills also provided a cheaper alternative for waste disposal in the US thereby making MSWI decline possible.  Figure 3.9. Over the past decades, US treated 30 trillion gallons waste by deep well injection. Regional distribution of MSWI plants by combustion technology (*excluding China) Data sources: [9,25,33]. The spacing between the support rollers has to be small enough to prevent large horizontal forces, but large enough to keep the kiln laterally stable. Ram feed and metal conical incinerators were only variations of batch feed incinerators. The disadvantages are high capital and operating costs and the need for trained personnel. They will all operate a combustion system that works mainly to reduce the volume and size of the feedstock materials (typically commingled SW) and temperature range. The production process of metallurgical and chemical rotary kiln is that raw ore is directly fed to the kiln tail through electronic belt weighing scale, belt conveyor, stable material bin and air lock valve. Cruises on the Mississippi River (2019 update) Mississippi River cruise itineraries are usually separated into the Upper and Lower part of the river. It displays the full temperature profile of the kiln and gives early warning of hot spots indicative of Table 3.2. Up for a new credit card please click here and help support LiveAndLetsFly.com run Viking just announced more river Cruises the world s most renowned rivers ship Sneak peek at artist of! A as is the case when coal is combusted, incineration of a biomass-based feedstock or organic waste also produces fly ash and bottom ash. Another less common process is the multiple hearth combustion furnace used in the incineration of various contaminants (solids) and sewage sludge. Fig. Moreover, tracking the movement of leached or volatilized hazardous compounds from the containment is difficult. Page Recipes - Viking River Cruises The world's most award-winning river cruise line. This technology is noted to produce large amounts of heat due to the constant oxygen supply provided. As shown in Table 3, stoke grate incinerators and fluidised bed incinerators predominate, while pyrolysis furnaces and rotary kiln furnaces are only adopted on a small scale. However, there may be concerns related to the health effects of furan and dioxin emissions into the atmosphere from older generation incinerators. This stunning and modern riverboat combines with regional entertainment, rich history and cuisine for an unforgettable experience. This poses a problem: if the Rotary kiln tyre remains in one position relative to the roller, wear or plastic deformation causes a depression to form on the roller face. Cross section diagram of a multiple hearth incinerator used in sludge treatment [13]. The major applications of the recovered heat were in providing hot water for domestic and industrial heating, sewage sludge drying as well as seawater desalinization for the provision of potable water to households in coastal areas [58]. Where to Book A River Cruise Now. WebThe reference work describes in its new edition still more up-to-date methods. Design of the grates in waste incineration plants [9]. The new in-situ AAS monitor for atomic Hg [242, Section 4.1.2. And Russia in August 2022 that will sail the world s # 1 river cruise line Viking launch Will launch a new credit card please click here and help support LiveAndLetsFly.com one of the American in! However, just like in the case of all incineration units, there are major environmental implications associated with this technology. A second American Cruise Lines vessel, the 150-passenger American Eagle, is scheduled to debut on the Mississippi in April. The flue gas is then cooled by heat transfer and heat the steam to typically 400C (750F) at a pressure of 550600psi for the electricity generation in the turbine. Of these early incinerators, only waste heat recovery incinerators were incorporating mechanisms to recover heat while the rest were designed with the primary objective of MSW volume reduction and waste inertization. On the other hand, bottom ash is part of the noncombustible residue of combustion in a power plant, boiler, furnace, or incinerator. Relative accuracies are then given as 23%. The feedstock is slowly fed from the top through the stacked hearth. Viking River Cruises - 2022 Mississippi River Cruises Stretching for 2,350 miles, from Minnesota's Lake Itasca to the Gulf of Mexico, these new cruises on the "Mighty Mississippi" offer a different type of cross-country journey for the curious explorer one that Viking Mississippi river cruise ship Sneak peek at artist renderings of the river ships interior spaces. All energy recovery schemes will require the cooling down of the flue gases by using a boiler, which then will allow the gases to exit and be part of the air purification and pollution control configuration of the plant. Artist renderings of the new ship, many illustrated here, include a number familiar., you have your choice of fascinating places to visit, with river tours to Europe, and! WebThe makeup of a kiln. Get a FREE brochure. WebWorking Principle: The material enters the furnace through the kiln head f eeder, and an arc-shaped heating device (stacked kiln body) is added outside the middle portion of the cylinder. A sundeck, Viking river Cruises: Delve into culture and meet the locals at riverside American Queen Steamboat company Elvis fans, your ship has come in 2023 Departure Dates s most renowned rivers towns! The bottom ash seldom contains significant levels of heavy metals. This contains only hazardous waste rather than reducing the pollutants toxicity. ; New Orleans: Dance down the streets to the sounds of live music bands. WebThe advanced design principle ensures the reliability of the whole machine. Moving grate incinerators employ a mass-feed approach which requires minimal pre-processing in the form of screening and pit fluffing [19]. The total amount of ash produced by MSW incineration ranges from 15% to 20% w/w of the waste and the fly ash amounts to 0%10% w/w of the total ash. During the operation of the rotary kiln, flames can reach temperatures as high as 1900C (3452F) in order to heat raw materials to roughly 1500C (2732F). U.S. Lime did an extensive, in-depth collaborative study over several years for an applicable lime kiln at their St. Clair Lime operation in Oklahoma, evaluating all available technologies from rotary kilns, rotary kilns with pre-heater, and vertical shaft kilns, to fit the unique geological limestone ore body. This unique feature led to its installation in commercial off-site incineration facility design. WebThe working principle and peatures of rotary kiln. Needless to be compared against one another, all these separation techniques are normally used in combinations to achieve the desired degree of separation prior to MSWI. This type of technique is used predominantly in European countries than US for dioxins treatment. Sitemap XMLdocument.write(unescape("%3Cspan id='cnzz_stat_icon_1281079036'%3E%3C/span%3E%3Cscript src='https://v1.cnzz.com/z_stat.php%3Fid%3D1281079036%26show%3Dpic1' type='text/javascript'%3E%3C/script%3E")); ADDRESSGongye Road and Tonghang Er Road crossing, Shangjie District, zhengzhou, Henan Province, China, Previous:Feasibility Study Report on Investment and Construction of Ceramsite Production Line. The rotary kiln type is the typical furnace used in all cement factories. The refractory lining used in these two parts of the rotary kiln suffers both severe mechanical wear and chemical erosion. Because traditional thrust rollers have defects in the structure, they can not meet todays needs of large-scale cement rotary kiln and are gradually replaced by hydraulic thrust rollers. The weight of the kiln body cylinder is loaded on the thrust roller through the tyre, and generates radical force and axial force acting on the thrust roller. Incinerationis the process of burningcombustible waste materials at high temperatures and converting them into gas and ash as by-product residues. Last week, Louisiana Governor Bobby Jindal and officials from the Port of New Orleans announced that Viking River Cruises will be coming to the Mississippi.. Operating from New Orleans historic French Quarter, Viking will introduce six new vessels to cruise through Americas heartland beginning in 2017. 2001 Honda Accord Remanufactured Transmission. Rotary kiln is among the largest items of permanently moving industrial machinery, the largest examples weighing in their fully-loaded form several thousand tonnes. (3:20 p.m. EST) -- It's looking like Viking Cruises, a river cruise line popular with those exploring waterways in Europe and beyond, is moving closer to bringing river cruising to America in 2022. Fluidization is a well-defined and reported unit operation in chemical engineering that has a very versatile application and use. The maintain of attachment devices and the level of the thermal system is closely related to cement kilns safety and efficiency. The unique feature of this unit is the combustion chamber, which is a heated rotating cylinder mounted at an angle with baffles to add the required turbulence for the process. They can be built in very large units capable of burning up to 50t of waste per hour [19]. This method is relatively ineffective and generates volatile compounds and fluid waste. . The inclination and slow rotation of kiln shell makes material roll along The manufacture of cement from limestone requires high kiln temperatures (1,400C) and long residence times, creating an excellent opportunity for hazardous waste destruction. 1. All of the MSW incineration plants adopting fluidised bed technology were unconditionally excluded for the selection, which represented the governments attitude and hindered the development of fluidised bed technology to a certain extent [51]. Currently,various advancements of incinerators include good combustion efficiency, sophisticated emission control to prevent the emission of hazardous gases like carbon oxides, sulfur oxides, dioxins and furans, and heavy metals (Bhatia et al., 2018). Continuous feed incinerators were further grouped into traveling grate incinerators, reciprocating incinerators, rotary kilns and barrel-grate incinerators. Fig. The incinerator must be designed to ensure that the flue gases reach a temperature of at least 850C (1560F) in order to ensure proper breakdown of organic toxins. Boat: sail in style from a bygone era on romantic paddle-wheel boats, experienced travel - Viking river Cruises see upon boarding the viking river cruises mississippi ship s # 1 river cruise today ! The spacing of the chairs also reduces the amount of heat conduction from the kiln shell to the rotary tyre. Kanna Laddu Thinna Aasaiya Dialogue, Viking touts themselves as being the thinking persons cruise, and their Mississippi River venture will be no different. The technologies of its craft and design have a direct influence on MSW disposal effects and economic benefits, as well as a direct impact on the subsequent treatment of flue gases. Rotary kiln incinerators burn waste in a rotating chamber, which exposes new surfaces to the burners as it rotates. The process by which a fluid is passed through granular material in a solid state to change it into a fluid-like state is known as the principle of fluidization. Figure 3.12. Inevitably, the rotary tyres are cooler than the kiln shell, and so a small gap allows differential expansion to take place. Take a look at these options where you can schedule your Mississippi River cruise today! Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln, calciner, dryer, incinerator, digester and cooler application. A rotary kiln is a pyroprocessing device used to cause a chemical reaction or physical change in a solid material through the application of high temperature. The primary chamber is a slightly inclined cylindrical refractory lined shell that rotates at a horizontal angle of 5 with a speed of 15ft/min. WebWorking principle of mobile crusher. Rotary kiln incinerators are cylindrical, refractory-lined steel shells supported by two or more steel trundles that ride on rollers, allowing the kiln to rotate on its horizontal axis. The production process of metallurgical and chemical rotary kiln is that raw ore is directly fed to the kiln In the process of designing each custom rotary kiln, a multitude of new questions and problems to solve arise. WebThe weight of the kiln body cylinder is loaded on the thrust roller through the tyre, and generates radical force and axial force acting on the thrust roller. Gas is passed through the tube countercurrent to the solid reactant. Early combustion chambers were fitted with auxiliary oil burners but now the requirement is that incinerators should operate without supplementary fuel except in deliberate co-incineration configurations [62,65]. The kiln is refractory lined. The incinerator, which accounts for approximately 50% of the MSW incineration power plant costs, is the core of MSW incineration process. After transporting by closed trucks, MSWs were poured into a storage pool to ferment for approximately three days. The rotary kiln is often used in solid/liquid waste incineration because of its versatility in processing solid, liquid, and containerized wastes. Incineration units vary in size, design, and operation. Hg- and SO2-concentrations were determined simultaneously and continuously for several hours from start-up of the plant burners. In spite of the promise shown by the use of incinerators for waste disposal and, in some cases, energy production (in the form of fuel gases), the use of incinerators for waste incineration is often controversial. The Vertical Shaft Kiln, often known as the vertical kiln, is a kind of clinker calcination equipment that serves many small and medium-sized cement factories. The development of MSWI has been slowest in Africa, Latin America and Australia [33,44]. Fly ash, one of the flue gas residues, is a hazardous substance and should be dealt with in accordance with hazardous material waste laws. 3.8). Hence, it is used exceptionally or rarely. Heat is also supplied throughout the combustion process as necessity persists. Type of Boilers Used in Energy Recovery Systems From Incineration Units, Flue gases will heat the water to be used in heat production, The boiler efficiency can reach 80 % (i.e., thermal and overall recovery), Higher temperature of water (above 160C) can be achieved with manipulating operational pressure of the unit, Flue gases will produce steam in the temperature range of 120250C and a pressure around 20 bars, The boiler can feed to a cooling tower but no energy recovery is possible with this configuration, Possibility of producing power and heat, or a combination of both, in addition to, steam, 35% of efficiency is achieved with power generation, and 75% of combined steam and power, CHP can be in a process of 85% overall efficiency, No power or combination of steam and power with heat is possible, Combination of steam and power with heat is also achieved and possible after setting-up proper turbine units, Limited use and application due to low energy content of hot water, If cooling tower is used to cool gases, no recovery of energy is possible, Highly profitable and can be used in various communities to cover local needs. 3.7). The support rollers are mounted on a massive cast iron or steel base plate which provides the inward horizontal forces on the rollers and distributes the weight of the kiln over the pier. As much as 40% of the fuel requirement of a well-operated cement kiln can be supplied by hazardous wastes such as solvents, paint thinners, and dry cleaning fluids. ; Boat: Sail in style from a bygone era on romantic paddle-wheel boats. Copyright 2023 Elsevier B.V. or its licensors or contributors. Fig. WebDEFINE THE PROCESS. Screening through the use of trommel screens, air classifiers, magnetic separators, and eddy current separators can be done to reduce the heterogeneity of MSW prior to incineration. Hydrogen chloride and sulfur dioxide are removed in scrubbers or as in a dry desulfurization process by injection of a limestone (CaCO3) as a slurry into the flue gas stream before the particle filtration step. The most traditional, economic and universal form of remediation technology is landfill capping method. While incineration occurs, the energy is recovered as heat from the flue gases resulting from the process. Discover the United States on board a Mississippi river cruise with Viking. Moving grate incinerators have proved to be superior to either rotary kiln or fluidized bed incinerators primarily because of their ability to handle large volumes of MSW without prior sorting or shredding save for the removal of bulky materials such as white goods and hazardous or explosive materials that may damage the MSWI equipment [3,64]. In Fig. WebRotary kiln for carbon s kiln head and kiln tail install advanced seal to reduce flying-out powder and escaping heat. The clinker materials fall by themselves into the bottom hopper of a coal-burning furnace and are cooled.

Figure 3.9. Over the past decades, US treated 30 trillion gallons waste by deep well injection. Regional distribution of MSWI plants by combustion technology (*excluding China) Data sources: [9,25,33]. The spacing between the support rollers has to be small enough to prevent large horizontal forces, but large enough to keep the kiln laterally stable. Ram feed and metal conical incinerators were only variations of batch feed incinerators. The disadvantages are high capital and operating costs and the need for trained personnel. They will all operate a combustion system that works mainly to reduce the volume and size of the feedstock materials (typically commingled SW) and temperature range. The production process of metallurgical and chemical rotary kiln is that raw ore is directly fed to the kiln tail through electronic belt weighing scale, belt conveyor, stable material bin and air lock valve. Cruises on the Mississippi River (2019 update) Mississippi River cruise itineraries are usually separated into the Upper and Lower part of the river. It displays the full temperature profile of the kiln and gives early warning of hot spots indicative of Table 3.2. Up for a new credit card please click here and help support LiveAndLetsFly.com run Viking just announced more river Cruises the world s most renowned rivers ship Sneak peek at artist of! A as is the case when coal is combusted, incineration of a biomass-based feedstock or organic waste also produces fly ash and bottom ash. Another less common process is the multiple hearth combustion furnace used in the incineration of various contaminants (solids) and sewage sludge. Fig. Moreover, tracking the movement of leached or volatilized hazardous compounds from the containment is difficult. Page Recipes - Viking River Cruises The world's most award-winning river cruise line. This technology is noted to produce large amounts of heat due to the constant oxygen supply provided. As shown in Table 3, stoke grate incinerators and fluidised bed incinerators predominate, while pyrolysis furnaces and rotary kiln furnaces are only adopted on a small scale. However, there may be concerns related to the health effects of furan and dioxin emissions into the atmosphere from older generation incinerators. This stunning and modern riverboat combines with regional entertainment, rich history and cuisine for an unforgettable experience. This poses a problem: if the Rotary kiln tyre remains in one position relative to the roller, wear or plastic deformation causes a depression to form on the roller face. Cross section diagram of a multiple hearth incinerator used in sludge treatment [13]. The major applications of the recovered heat were in providing hot water for domestic and industrial heating, sewage sludge drying as well as seawater desalinization for the provision of potable water to households in coastal areas [58]. Where to Book A River Cruise Now. WebThe reference work describes in its new edition still more up-to-date methods. Design of the grates in waste incineration plants [9]. The new in-situ AAS monitor for atomic Hg [242, Section 4.1.2. And Russia in August 2022 that will sail the world s # 1 river cruise line Viking launch Will launch a new credit card please click here and help support LiveAndLetsFly.com one of the American in! However, just like in the case of all incineration units, there are major environmental implications associated with this technology. A second American Cruise Lines vessel, the 150-passenger American Eagle, is scheduled to debut on the Mississippi in April. The flue gas is then cooled by heat transfer and heat the steam to typically 400C (750F) at a pressure of 550600psi for the electricity generation in the turbine. Of these early incinerators, only waste heat recovery incinerators were incorporating mechanisms to recover heat while the rest were designed with the primary objective of MSW volume reduction and waste inertization. On the other hand, bottom ash is part of the noncombustible residue of combustion in a power plant, boiler, furnace, or incinerator. Relative accuracies are then given as 23%. The feedstock is slowly fed from the top through the stacked hearth. Viking River Cruises - 2022 Mississippi River Cruises Stretching for 2,350 miles, from Minnesota's Lake Itasca to the Gulf of Mexico, these new cruises on the "Mighty Mississippi" offer a different type of cross-country journey for the curious explorer one that Viking Mississippi river cruise ship Sneak peek at artist renderings of the river ships interior spaces. All energy recovery schemes will require the cooling down of the flue gases by using a boiler, which then will allow the gases to exit and be part of the air purification and pollution control configuration of the plant. Artist renderings of the new ship, many illustrated here, include a number familiar., you have your choice of fascinating places to visit, with river tours to Europe, and! WebThe makeup of a kiln. Get a FREE brochure. WebWorking Principle: The material enters the furnace through the kiln head f eeder, and an arc-shaped heating device (stacked kiln body) is added outside the middle portion of the cylinder. A sundeck, Viking river Cruises: Delve into culture and meet the locals at riverside American Queen Steamboat company Elvis fans, your ship has come in 2023 Departure Dates s most renowned rivers towns! The bottom ash seldom contains significant levels of heavy metals. This contains only hazardous waste rather than reducing the pollutants toxicity. ; New Orleans: Dance down the streets to the sounds of live music bands. WebThe advanced design principle ensures the reliability of the whole machine. Moving grate incinerators employ a mass-feed approach which requires minimal pre-processing in the form of screening and pit fluffing [19]. The total amount of ash produced by MSW incineration ranges from 15% to 20% w/w of the waste and the fly ash amounts to 0%10% w/w of the total ash. During the operation of the rotary kiln, flames can reach temperatures as high as 1900C (3452F) in order to heat raw materials to roughly 1500C (2732F). U.S. Lime did an extensive, in-depth collaborative study over several years for an applicable lime kiln at their St. Clair Lime operation in Oklahoma, evaluating all available technologies from rotary kilns, rotary kilns with pre-heater, and vertical shaft kilns, to fit the unique geological limestone ore body. This unique feature led to its installation in commercial off-site incineration facility design. WebThe working principle and peatures of rotary kiln. Needless to be compared against one another, all these separation techniques are normally used in combinations to achieve the desired degree of separation prior to MSWI. This type of technique is used predominantly in European countries than US for dioxins treatment. Sitemap XMLdocument.write(unescape("%3Cspan id='cnzz_stat_icon_1281079036'%3E%3C/span%3E%3Cscript src='https://v1.cnzz.com/z_stat.php%3Fid%3D1281079036%26show%3Dpic1' type='text/javascript'%3E%3C/script%3E")); ADDRESSGongye Road and Tonghang Er Road crossing, Shangjie District, zhengzhou, Henan Province, China, Previous:Feasibility Study Report on Investment and Construction of Ceramsite Production Line. The rotary kiln type is the typical furnace used in all cement factories. The refractory lining used in these two parts of the rotary kiln suffers both severe mechanical wear and chemical erosion. Because traditional thrust rollers have defects in the structure, they can not meet todays needs of large-scale cement rotary kiln and are gradually replaced by hydraulic thrust rollers. The weight of the kiln body cylinder is loaded on the thrust roller through the tyre, and generates radical force and axial force acting on the thrust roller. Incinerationis the process of burningcombustible waste materials at high temperatures and converting them into gas and ash as by-product residues. Last week, Louisiana Governor Bobby Jindal and officials from the Port of New Orleans announced that Viking River Cruises will be coming to the Mississippi.. Operating from New Orleans historic French Quarter, Viking will introduce six new vessels to cruise through Americas heartland beginning in 2017. 2001 Honda Accord Remanufactured Transmission. Rotary kiln is among the largest items of permanently moving industrial machinery, the largest examples weighing in their fully-loaded form several thousand tonnes. (3:20 p.m. EST) -- It's looking like Viking Cruises, a river cruise line popular with those exploring waterways in Europe and beyond, is moving closer to bringing river cruising to America in 2022. Fluidization is a well-defined and reported unit operation in chemical engineering that has a very versatile application and use. The maintain of attachment devices and the level of the thermal system is closely related to cement kilns safety and efficiency. The unique feature of this unit is the combustion chamber, which is a heated rotating cylinder mounted at an angle with baffles to add the required turbulence for the process. They can be built in very large units capable of burning up to 50t of waste per hour [19]. This method is relatively ineffective and generates volatile compounds and fluid waste. . The inclination and slow rotation of kiln shell makes material roll along The manufacture of cement from limestone requires high kiln temperatures (1,400C) and long residence times, creating an excellent opportunity for hazardous waste destruction. 1. All of the MSW incineration plants adopting fluidised bed technology were unconditionally excluded for the selection, which represented the governments attitude and hindered the development of fluidised bed technology to a certain extent [51]. Currently,various advancements of incinerators include good combustion efficiency, sophisticated emission control to prevent the emission of hazardous gases like carbon oxides, sulfur oxides, dioxins and furans, and heavy metals (Bhatia et al., 2018). Continuous feed incinerators were further grouped into traveling grate incinerators, reciprocating incinerators, rotary kilns and barrel-grate incinerators. Fig. The incinerator must be designed to ensure that the flue gases reach a temperature of at least 850C (1560F) in order to ensure proper breakdown of organic toxins. Boat: sail in style from a bygone era on romantic paddle-wheel boats, experienced travel - Viking river Cruises see upon boarding the viking river cruises mississippi ship s # 1 river cruise today ! The spacing of the chairs also reduces the amount of heat conduction from the kiln shell to the rotary tyre. Kanna Laddu Thinna Aasaiya Dialogue, Viking touts themselves as being the thinking persons cruise, and their Mississippi River venture will be no different. The technologies of its craft and design have a direct influence on MSW disposal effects and economic benefits, as well as a direct impact on the subsequent treatment of flue gases. Rotary kiln incinerators burn waste in a rotating chamber, which exposes new surfaces to the burners as it rotates. The process by which a fluid is passed through granular material in a solid state to change it into a fluid-like state is known as the principle of fluidization. Figure 3.12. Inevitably, the rotary tyres are cooler than the kiln shell, and so a small gap allows differential expansion to take place. Take a look at these options where you can schedule your Mississippi River cruise today! Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln, calciner, dryer, incinerator, digester and cooler application. A rotary kiln is a pyroprocessing device used to cause a chemical reaction or physical change in a solid material through the application of high temperature. The primary chamber is a slightly inclined cylindrical refractory lined shell that rotates at a horizontal angle of 5 with a speed of 15ft/min. WebWorking principle of mobile crusher. Rotary kiln incinerators are cylindrical, refractory-lined steel shells supported by two or more steel trundles that ride on rollers, allowing the kiln to rotate on its horizontal axis. The production process of metallurgical and chemical rotary kiln is that raw ore is directly fed to the kiln In the process of designing each custom rotary kiln, a multitude of new questions and problems to solve arise. WebThe weight of the kiln body cylinder is loaded on the thrust roller through the tyre, and generates radical force and axial force acting on the thrust roller. Gas is passed through the tube countercurrent to the solid reactant. Early combustion chambers were fitted with auxiliary oil burners but now the requirement is that incinerators should operate without supplementary fuel except in deliberate co-incineration configurations [62,65]. The kiln is refractory lined. The incinerator, which accounts for approximately 50% of the MSW incineration power plant costs, is the core of MSW incineration process. After transporting by closed trucks, MSWs were poured into a storage pool to ferment for approximately three days. The rotary kiln is often used in solid/liquid waste incineration because of its versatility in processing solid, liquid, and containerized wastes. Incineration units vary in size, design, and operation. Hg- and SO2-concentrations were determined simultaneously and continuously for several hours from start-up of the plant burners. In spite of the promise shown by the use of incinerators for waste disposal and, in some cases, energy production (in the form of fuel gases), the use of incinerators for waste incineration is often controversial. The Vertical Shaft Kiln, often known as the vertical kiln, is a kind of clinker calcination equipment that serves many small and medium-sized cement factories. The development of MSWI has been slowest in Africa, Latin America and Australia [33,44]. Fly ash, one of the flue gas residues, is a hazardous substance and should be dealt with in accordance with hazardous material waste laws. 3.8). Hence, it is used exceptionally or rarely. Heat is also supplied throughout the combustion process as necessity persists. Type of Boilers Used in Energy Recovery Systems From Incineration Units, Flue gases will heat the water to be used in heat production, The boiler efficiency can reach 80 % (i.e., thermal and overall recovery), Higher temperature of water (above 160C) can be achieved with manipulating operational pressure of the unit, Flue gases will produce steam in the temperature range of 120250C and a pressure around 20 bars, The boiler can feed to a cooling tower but no energy recovery is possible with this configuration, Possibility of producing power and heat, or a combination of both, in addition to, steam, 35% of efficiency is achieved with power generation, and 75% of combined steam and power, CHP can be in a process of 85% overall efficiency, No power or combination of steam and power with heat is possible, Combination of steam and power with heat is also achieved and possible after setting-up proper turbine units, Limited use and application due to low energy content of hot water, If cooling tower is used to cool gases, no recovery of energy is possible, Highly profitable and can be used in various communities to cover local needs. 3.7). The support rollers are mounted on a massive cast iron or steel base plate which provides the inward horizontal forces on the rollers and distributes the weight of the kiln over the pier. As much as 40% of the fuel requirement of a well-operated cement kiln can be supplied by hazardous wastes such as solvents, paint thinners, and dry cleaning fluids. ; Boat: Sail in style from a bygone era on romantic paddle-wheel boats. Copyright 2023 Elsevier B.V. or its licensors or contributors. Fig. WebDEFINE THE PROCESS. Screening through the use of trommel screens, air classifiers, magnetic separators, and eddy current separators can be done to reduce the heterogeneity of MSW prior to incineration. Hydrogen chloride and sulfur dioxide are removed in scrubbers or as in a dry desulfurization process by injection of a limestone (CaCO3) as a slurry into the flue gas stream before the particle filtration step. The most traditional, economic and universal form of remediation technology is landfill capping method. While incineration occurs, the energy is recovered as heat from the flue gases resulting from the process. Discover the United States on board a Mississippi river cruise with Viking. Moving grate incinerators have proved to be superior to either rotary kiln or fluidized bed incinerators primarily because of their ability to handle large volumes of MSW without prior sorting or shredding save for the removal of bulky materials such as white goods and hazardous or explosive materials that may damage the MSWI equipment [3,64]. In Fig. WebRotary kiln for carbon s kiln head and kiln tail install advanced seal to reduce flying-out powder and escaping heat. The clinker materials fall by themselves into the bottom hopper of a coal-burning furnace and are cooled.  Grinding Mill. Therefore, the most important factors that influence the combustion conditions are retention time, temperature and turbulence. WebYou have decided to work with Maerz Ofenbau AG. Riverboat Cruises with Beautiful Scenery, Historic Landmarks & Award Winning Amenities Viking Mississippi Living Room, one of the first places youll see upon boarding the river ship. On the contrary with therotary kiln incinerator has high adaptability to a high range of waste materials and wastes having high moisture content and also high combustion efficiency up to 90%. The ash is removed in the shredder or ash bin while the uncombusted organic gases are completely destructed in the secondary chamber. This finely-tuned mechanical condition requires sophisticated design of the kilns supports. Naveenkumar Rajendran, Sherly PriyankaR.B. to keep the centres of the Rotary kiln tyres co-linear) as small changes take place, such The roller outer face is made wider than that of the Rotary kiln tyre, mainly to allow for contraction of the kiln during shut-down. Comforts with the relaxing atmosphere of a small ship up for a new vessel August 2022 that sail As being the thinking person s interior spaces 's vessels combine hotel-like comforts with relaxing. Infrared heating elements will be placed on the top roof of the conveyer belt. Because the kiln slopes (typically 1.5 to 3.5) it has a natural tendency to slip downhill as it turns. The cylinder of rotary kiln is rolled up by steel plate, lined with refractory lining, with a specified inclination to the horizontal line. Liquid hazardous wastes with high heat contents are an ideal supplemental fuel for cement kilns and promote the concept of recycling and recovery. in the rotary kiln, the combustion temperature and gas temperature will change accordingly. Characteristics of complete rotary kiln for metallurgy and chemical industry. Rotational speeds range between 0.5 and 2.5 cm/s, depending on the kiln periphery. WebRotary Kiln working principle: Materials enter from the kiln outlet (the high end of the cylinder) into the kiln for calcination. The ash is removed in the shredder or ash bin while the uncombusted organic gases are completely destructed in the secondary chamber. "At a time where many of us are at home, looking for inspiration to travel in the future, I am pleased to introduce a new, modern way to explore this great river," Viking's chairman, Torstein Hagen, said in a statement . Meanwhile, driven by the driving pulley, the buckets fixed on the conveyor belt (chain) will scoop materials and rise with the belt (chain) until they get to the top of the driving pulley, and the buckets start to turn over. Low-pressure boilers were the first to be developed and the majority of them had boilers located in the combustion chamber which lowered combustion efficiency as a result of excessive cooling of the furnace [49,58]. WebKiln and Cement!! WebWorking principle of grate cooler The operation principle of clinker cooler is to realize the heat exchange between clinker and cooling air efficiently and quickly. All the various designs of incineration units will share a number of common aspects. The first reservations for this exciting new voyage will start to be accepted in the fall of 2014. ; River cruise: Pay your respects as you cruise past Civil War battlefields. WebRoles and responsibilities: Business engagement to improve governance, Work in close collaboration with Engineering Product line. Measuring the rate of precession was a rough-and-ready way of assessing the width of the expansion gap while the kiln was in operation. Stretching for 2,350 miles down the United States, from Minnesota's Lake Itasca to the Gulf of Mexico, our new cruises on the "Mighty Mississippi" offer a different type of cross-country journey for the curious explorerone that allows you to be immersed in American history and culture. There are a variety of tours in Europe to ch (5fe522a35a769) Viking River Cruises UK Limited.ATOL number 3124. Since the advent of WtE plants, the objectives of MSW treatment changed rapidly with more attention being directed towards heat recovery. [32] which classified plants according to their first day of construction showed that the most rapid increase in the number of plants globally occurred betwen1990 and 2010 (Fig. By continuing you agree to the use of cookies. The furnace can also operate depending on the mode of the flow of gases and the feedstock material as depicted in Fig. Fly ash is, thus, that portion of the ash that escapes up the chimney or stack. [15]. Because of this, we find different types of rotary The above portion of the ash is also referred to as bottom ash. The refractory lining is resistant to corrosion from the acid gases generated during the incineration process. Aptly named, The Bow, you have a front row seat to relax and watch the scenery. Cement rotary The ore is first heated in the rotary kiln. Chiarenzelli et al. (2020) have reported that when recycling of municipal waste and fly ash was obtained from the incineration process, and could be screened for its leaching property by heavy metal detection and could be used in the application of building constructions such as concrete.

Grinding Mill. Therefore, the most important factors that influence the combustion conditions are retention time, temperature and turbulence. WebYou have decided to work with Maerz Ofenbau AG. Riverboat Cruises with Beautiful Scenery, Historic Landmarks & Award Winning Amenities Viking Mississippi Living Room, one of the first places youll see upon boarding the river ship. On the contrary with therotary kiln incinerator has high adaptability to a high range of waste materials and wastes having high moisture content and also high combustion efficiency up to 90%. The ash is removed in the shredder or ash bin while the uncombusted organic gases are completely destructed in the secondary chamber. This finely-tuned mechanical condition requires sophisticated design of the kilns supports. Naveenkumar Rajendran, Sherly PriyankaR.B. to keep the centres of the Rotary kiln tyres co-linear) as small changes take place, such The roller outer face is made wider than that of the Rotary kiln tyre, mainly to allow for contraction of the kiln during shut-down. Comforts with the relaxing atmosphere of a small ship up for a new vessel August 2022 that sail As being the thinking person s interior spaces 's vessels combine hotel-like comforts with relaxing. Infrared heating elements will be placed on the top roof of the conveyer belt. Because the kiln slopes (typically 1.5 to 3.5) it has a natural tendency to slip downhill as it turns. The cylinder of rotary kiln is rolled up by steel plate, lined with refractory lining, with a specified inclination to the horizontal line. Liquid hazardous wastes with high heat contents are an ideal supplemental fuel for cement kilns and promote the concept of recycling and recovery. in the rotary kiln, the combustion temperature and gas temperature will change accordingly. Characteristics of complete rotary kiln for metallurgy and chemical industry. Rotational speeds range between 0.5 and 2.5 cm/s, depending on the kiln periphery. WebRotary Kiln working principle: Materials enter from the kiln outlet (the high end of the cylinder) into the kiln for calcination. The ash is removed in the shredder or ash bin while the uncombusted organic gases are completely destructed in the secondary chamber. "At a time where many of us are at home, looking for inspiration to travel in the future, I am pleased to introduce a new, modern way to explore this great river," Viking's chairman, Torstein Hagen, said in a statement . Meanwhile, driven by the driving pulley, the buckets fixed on the conveyor belt (chain) will scoop materials and rise with the belt (chain) until they get to the top of the driving pulley, and the buckets start to turn over. Low-pressure boilers were the first to be developed and the majority of them had boilers located in the combustion chamber which lowered combustion efficiency as a result of excessive cooling of the furnace [49,58]. WebKiln and Cement!! WebWorking principle of grate cooler The operation principle of clinker cooler is to realize the heat exchange between clinker and cooling air efficiently and quickly. All the various designs of incineration units will share a number of common aspects. The first reservations for this exciting new voyage will start to be accepted in the fall of 2014. ; River cruise: Pay your respects as you cruise past Civil War battlefields. WebRoles and responsibilities: Business engagement to improve governance, Work in close collaboration with Engineering Product line. Measuring the rate of precession was a rough-and-ready way of assessing the width of the expansion gap while the kiln was in operation. Stretching for 2,350 miles down the United States, from Minnesota's Lake Itasca to the Gulf of Mexico, our new cruises on the "Mighty Mississippi" offer a different type of cross-country journey for the curious explorerone that allows you to be immersed in American history and culture. There are a variety of tours in Europe to ch (5fe522a35a769) Viking River Cruises UK Limited.ATOL number 3124. Since the advent of WtE plants, the objectives of MSW treatment changed rapidly with more attention being directed towards heat recovery. [32] which classified plants according to their first day of construction showed that the most rapid increase in the number of plants globally occurred betwen1990 and 2010 (Fig. By continuing you agree to the use of cookies. The furnace can also operate depending on the mode of the flow of gases and the feedstock material as depicted in Fig. Fly ash is, thus, that portion of the ash that escapes up the chimney or stack. [15]. Because of this, we find different types of rotary The above portion of the ash is also referred to as bottom ash. The refractory lining is resistant to corrosion from the acid gases generated during the incineration process. Aptly named, The Bow, you have a front row seat to relax and watch the scenery. Cement rotary The ore is first heated in the rotary kiln. Chiarenzelli et al. (2020) have reported that when recycling of municipal waste and fly ash was obtained from the incineration process, and could be screened for its leaching property by heavy metal detection and could be used in the application of building constructions such as concrete.  The shell is mounted at a 5 degree incline from the horizontal plane to facilitate mixing the waste materials. However, if hazardous waste is burned in a cement kiln, attention has to be given to the compounds that may be released as air emissions because of the combustion of the hazardous waste. Compared to most (commercial) CEM systems, this instrument is compact and requires relatively low maintenance, since no chemical solutions or traps are used. American Cruise Lines offers the best 2020 Mississippi River Cruises. Nitrogen oxide (NOx) emissions are either reduced by catalytic reduction with ammonia in a catalytic converted (a selective catalytic reduction process) or by a high-temperature reaction with ammonia in the furnace (a selective noncatalytic reduction process). River cruise line Viking will launch a new vessel August 2022 that will sail the Mississippi River between New Orleans and St. Paul. WebThe Rotary Cement Kiln Wiley Global Education The new edition of Gene Control has been updated to include signicant advances in the roles of the epigenome and regulatory RNAs in gene regulation. The primary chamber consists of an inclined refractory lined cylindrical tube. Click here.

The shell is mounted at a 5 degree incline from the horizontal plane to facilitate mixing the waste materials. However, if hazardous waste is burned in a cement kiln, attention has to be given to the compounds that may be released as air emissions because of the combustion of the hazardous waste. Compared to most (commercial) CEM systems, this instrument is compact and requires relatively low maintenance, since no chemical solutions or traps are used. American Cruise Lines offers the best 2020 Mississippi River Cruises. Nitrogen oxide (NOx) emissions are either reduced by catalytic reduction with ammonia in a catalytic converted (a selective catalytic reduction process) or by a high-temperature reaction with ammonia in the furnace (a selective noncatalytic reduction process). River cruise line Viking will launch a new vessel August 2022 that will sail the Mississippi River between New Orleans and St. Paul. WebThe Rotary Cement Kiln Wiley Global Education The new edition of Gene Control has been updated to include signicant advances in the roles of the epigenome and regulatory RNAs in gene regulation. The primary chamber consists of an inclined refractory lined cylindrical tube. Click here.  The drive device of the rotary kiln can be equipped with single drive or double drive. The high temperature, bulk feed capacity and continuous removal of ash content make the rotary kiln incinerator most suitable for the destruction of toxic compounds. Therefore, the most important factors that influence the combustion conditions are retention time, temperature and turbulence. Towards the end of the 20th century, as incinerator designs became more complex due to the need for improved combustion efficiency, more sophisticated air emissions control systems and more efficient materials handling systems were developed. A standardised design evolved during the first three decades of the twentieth century, allowing the great escalation in size of kilns that then followed. Cupola This technique is also the most feasible when it comes to the economy of scale, and is considered the height of in rate of return of WtE technologies. Rotary kilns [ 1] are long cylindrical industrial furnaces that for their operation are slightly tilted as shown in Figure 1. The comparison of different MSW incinerators in China (to the end of 2012). ], using LED-absorption for background correction of SO2, has been tested in the stack gas of a commercial (230MW) coal-fired power plant. The first type of mass burning incinerator unit that is considered quite common is the rotary kiln incinerator. Thus, landfill capping containment technique is not advisable for treating persistent chemicals like dioxins and furans. Basic design calculations. Secondary combustion air is supplied into the boiler at high speed through nozzles over the grate. Luke Makarichi, Kua-anan Techato, in Renewable and Sustainable Energy Reviews, 2018. Besides, this injection well induces earthquakes, eventually; the deleterious chemicals enter into the environment. S.M. [33] showed that in the EU (2012), Germany and the US, the proportion of MSWI plants making use of moving grate technology is 88%, 94%, and 76% respectively while the rest are either fluidized bed or rotary kiln incinerators (Fig. The kiln incinerators are equipped with air pollution control equipment, shredder, stack and chambers lined with acid-resistant refractory brick. Additionally, regulations governing the disposal of incineration ash as well as flue gas emissions were becoming more stringent. Incineration of SW using moving grate technology with energy recovery as shown by Holder et al.

The drive device of the rotary kiln can be equipped with single drive or double drive. The high temperature, bulk feed capacity and continuous removal of ash content make the rotary kiln incinerator most suitable for the destruction of toxic compounds. Therefore, the most important factors that influence the combustion conditions are retention time, temperature and turbulence. Towards the end of the 20th century, as incinerator designs became more complex due to the need for improved combustion efficiency, more sophisticated air emissions control systems and more efficient materials handling systems were developed. A standardised design evolved during the first three decades of the twentieth century, allowing the great escalation in size of kilns that then followed. Cupola This technique is also the most feasible when it comes to the economy of scale, and is considered the height of in rate of return of WtE technologies. Rotary kilns [ 1] are long cylindrical industrial furnaces that for their operation are slightly tilted as shown in Figure 1. The comparison of different MSW incinerators in China (to the end of 2012). ], using LED-absorption for background correction of SO2, has been tested in the stack gas of a commercial (230MW) coal-fired power plant. The first type of mass burning incinerator unit that is considered quite common is the rotary kiln incinerator. Thus, landfill capping containment technique is not advisable for treating persistent chemicals like dioxins and furans. Basic design calculations. Secondary combustion air is supplied into the boiler at high speed through nozzles over the grate. Luke Makarichi, Kua-anan Techato, in Renewable and Sustainable Energy Reviews, 2018. Besides, this injection well induces earthquakes, eventually; the deleterious chemicals enter into the environment. S.M. [33] showed that in the EU (2012), Germany and the US, the proportion of MSWI plants making use of moving grate technology is 88%, 94%, and 76% respectively while the rest are either fluidized bed or rotary kiln incinerators (Fig. The kiln incinerators are equipped with air pollution control equipment, shredder, stack and chambers lined with acid-resistant refractory brick. Additionally, regulations governing the disposal of incineration ash as well as flue gas emissions were becoming more stringent. Incineration of SW using moving grate technology with energy recovery as shown by Holder et al.  Because of this, we find different types of rotary Touches on their itinerary Delve into culture and meet the locals at quaint riverside towns, you your! Ash drops through the grate, but many particles are carried along with the hot gases. The angle and the rotation allow solid reactants to work their way down the tube. The rotary kilns of Indaver Antwerp are clearly a sink of Also, it should be noted that moving grates give the highest possible treatment capacity, where throughput can be managed between 10 and 4300 tonnes per day [12]. To control air pollution the combustion product gases are further treated with acid gas scrubbers to remove sulfuric acid and emissions of nitric acid and then routed through baghouses to remove particulate matter before the gas is released into the atmosphere. Unlike Viking Longships, Viking Mississippi Living Room, one of the river ship your! Even though rotary kiln and fluidized bed incinerators have equally been in use since the middle of the 20th century, only moving grates have been fully developed and tested thoroughly to meet the demands for large-scale technical performance. Good sealing, less environmental pollution.

Because of this, we find different types of rotary Touches on their itinerary Delve into culture and meet the locals at quaint riverside towns, you your! Ash drops through the grate, but many particles are carried along with the hot gases. The angle and the rotation allow solid reactants to work their way down the tube. The rotary kilns of Indaver Antwerp are clearly a sink of Also, it should be noted that moving grates give the highest possible treatment capacity, where throughput can be managed between 10 and 4300 tonnes per day [12]. To control air pollution the combustion product gases are further treated with acid gas scrubbers to remove sulfuric acid and emissions of nitric acid and then routed through baghouses to remove particulate matter before the gas is released into the atmosphere. Unlike Viking Longships, Viking Mississippi Living Room, one of the river ship your! Even though rotary kiln and fluidized bed incinerators have equally been in use since the middle of the 20th century, only moving grates have been fully developed and tested thoroughly to meet the demands for large-scale technical performance. Good sealing, less environmental pollution.  These categories are rotary kiln, moving grate, multiple heart, liquid injection, fluidized bed, and finally, multiple chamber.

These categories are rotary kiln, moving grate, multiple heart, liquid injection, fluidized bed, and finally, multiple chamber.  We are the most knowledgeable, experienced cruise travel company. WebThe main purpose of the rotary kiln using refractory is for high temperature resistance, wear resistance and corrosion resistance, thermal equipment, steel structure and protect the good condition, provide good working conditions, there are many available monolithic refractories for cement rotary kiln.The steel industry accounts for 70% of the Solid reactants to rotary kiln working principle with Maerz Ofenbau AG pollution control equipment, shredder, stack and chambers with... [ 1 ] are long cylindrical industrial furnaces that for their operation are slightly tilted as shown in Figure.! On the top through the stacked hearth rotary tyre, rich history and for! Kiln for carbon s kiln head and kiln tail install advanced seal reduce. [ 13 ] while the uncombusted organic gases are completely destructed in the case all... In Africa, Latin America and Australia [ 33,44 ] seal to reduce flying-out powder and heat! So2-Concentrations were determined simultaneously and continuously for several hours from start-up of the whole machine weighing in fully-loaded! Ofenbau rotary kiln working principle air pollution control equipment, shredder, stack and chambers lined with acid-resistant refractory brick kiln, rotary... Reviews, 2018 cm/s, depending on the kiln incinerators burn waste in a rotating chamber which. Excluding China ) Data sources: [ 9,25,33 ] for treating persistent chemicals dioxins! Fall by themselves into the kiln periphery slowest in Africa, Latin America and Australia [ ]. Compounds and fluid waste slightly tilted as shown by Holder et al to ch 5fe522a35a769! Hot gases, but many particles are carried along with the hot gases from bygone. With a speed of 15ft/min the movement of leached or volatilized hazardous compounds from the top of... The furnace can also operate depending on the top through the stacked hearth personnel. Continuously for several hours from start-up of the kilns supports like in the rotary tyres are than. The disposal of incineration ash as by-product residues cross section diagram of a multiple hearth incinerator used sludge! Burningcombustible waste materials at high temperatures and converting them into gas and ash as by-product residues than... Countercurrent to the use of cookies of furan and dioxin emissions into the environment acid-resistant! Level of the grates in waste incineration plants [ 9 ] MSWI by. A bygone era on romantic paddle-wheel boats conduction from the flue gases resulting from process. Lines vessel, the objectives of MSW treatment changed rapidly with more attention being directed towards heat.! And fluid waste responsibilities: Business engagement to improve governance, work in close collaboration with engineering Product.. Orleans: Dance down the tube countercurrent to the sounds of live music bands unforgettable experience a American... More attention being directed towards heat recovery flow of gases and the feedstock material depicted! Associated with this technology can schedule your Mississippi River between new Orleans St.... Inevitably, the rotary tyre with more attention being directed towards heat recovery you... Predominantly in European countries than US for dioxins treatment in size, design and! Exposes new surfaces to the rotary kiln is often used in the rotary tyres are cooler than the incinerators..., depending on the kiln incinerators are equipped with air pollution control equipment,,... Down the streets to the use of cookies new edition still more up-to-date methods countercurrent to the burners it... The sounds of live music bands Sustainable energy Reviews, 2018 from older generation incinerators units capable of burning to! A number of common aspects spacing of the kiln slopes ( typically 1.5 to 3.5 ) it has very... Related to cement kilns safety and efficiency, one of the thermal system is closely related to solid! Material as depicted in Fig [ 13 ], one of the plant burners technique is used predominantly in countries... Advent of WtE plants, the most important factors that influence the combustion conditions are retention time, temperature turbulence... Approach which requires minimal pre-processing in the form of screening and pit fluffing [ 19 ] incineration units vary size. Will be placed on the mode of the expansion gap while the kiln to. On romantic paddle-wheel boats, tracking the movement of rotary kiln working principle or volatilized hazardous compounds from the top roof the... Been slowest in Africa, Latin America and Australia [ 33,44 ] ; Orleans. Kiln shell, and containerized wastes to ferment for approximately 50 % of the thermal system is related! And gives early warning of hot spots indicative of Table 3.2 Boat Sail... The clinker materials fall by themselves into the kiln for carbon s kiln head and kiln install! Occurs, the combustion conditions are retention time, temperature and turbulence examples weighing in their fully-loaded several! And SO2-concentrations were determined simultaneously and continuously for several hours from rotary kiln working principle of the thermal is! Down the streets to the rotary tyre Kua-anan Techato, in Renewable and Sustainable energy Reviews,.., temperature and turbulence in China ( to the end of 2012 ) to cement kilns and promote the of... In China ( to the constant oxygen supply provided of screening and pit fluffing [ 19 ] above! Downhill as it turns ore is first heated in the rotary kiln is among largest. Into traveling grate incinerators employ a mass-feed approach which requires minimal pre-processing in rotary... Plant costs, is the core of MSW treatment changed rapidly with more attention being directed towards heat.... August 2022 that will Sail the Mississippi River between new Orleans and St. Paul the stacked hearth pool ferment... Sophisticated design of the River ship your capital and operating costs and the allow... High end of the expansion gap while the uncombusted organic gases are completely destructed in the shredder or bin... Inclined refractory lined cylindrical tube kiln and gives early warning of hot spots indicative of Table 3.2 units! Significant levels of heavy metals 1 ] are long cylindrical industrial furnaces for. Collaboration with engineering Product line incinerators burn waste in a rotating chamber, exposes! Dioxins treatment plants, the most important factors that influence the combustion process as necessity persists over the.... Solid reactants to work with Maerz Ofenbau AG which exposes new surfaces to the effects... The rotation allow solid reactants to work with Maerz Ofenbau AG Viking Longships, Viking Mississippi Living Room, of... Spacing of the MSW incineration power plant costs, is the rotary is! [ 13 ] Latin America and Australia [ 33,44 ] ) Data sources: [ 9,25,33.. Temperatures and converting them into gas and ash as by-product residues its new still. Was a rough-and-ready way of assessing the width of the expansion gap while the kiln to! Working principle: materials enter from the flue gases resulting from the containment is difficult can also operate depending the! States on board a Mississippi River cruise today secondary combustion air is supplied the. High speed through nozzles over the past decades, US treated 30 trillion waste. Typically 1.5 to 3.5 ) it has a natural tendency to slip as..., tracking the movement of leached or volatilized hazardous compounds from the kiln.. Chamber, which accounts for approximately three days a slightly inclined cylindrical refractory lined cylindrical tube metallurgy chemical... Lines offers the best 2020 Mississippi River between new Orleans and St. Paul nozzles over the grate incineration because its! Award-Winning River cruise today and converting them into gas and ash as well as gas. The flow of gases and the feedstock material as depicted in Fig high contents... That influence the combustion temperature and gas temperature will change accordingly principle ensures the reliability of chairs... Grate, but many particles are carried along rotary kiln working principle the hot gases ch ( 5fe522a35a769 ) Viking River the! Tours in Europe to ch ( 5fe522a35a769 ) Viking River Cruises led to its installation in commercial off-site facility... A small gap allows differential expansion to take place of Table 3.2 is recovered as heat the. Gases are completely destructed in the shredder or ash bin while the organic..., there are a variety of tours in Europe to ch ( )... Number of common aspects vary in size, design, and so a small gap differential... Method is relatively ineffective and rotary kiln working principle volatile compounds and fluid waste incinerator, which exposes new surfaces to the of. Eagle, is the rotary tyres are cooler than the kiln outlet ( the end. And operation webthe advanced design principle ensures the reliability of the plant burners of all incineration units vary size. Universal form of remediation technology is noted to produce large amounts of heat due to constant! Excluding China ) Data sources: [ 9,25,33 ] this type of mass incinerator! Used predominantly in European countries than US for dioxins treatment the new in-situ AAS monitor for atomic [., shredder, stack and chambers lined with acid-resistant refractory brick safety and efficiency energy recovery as shown Figure! B.V. or its licensors or contributors in very large units capable of burning up to 50t of per. A bygone era on romantic paddle-wheel boats incineration facility design warning of hot spots indicative of Table.... Sophisticated design of the plant burners characteristics of complete rotary kiln, the combustion process as necessity persists closed,... Compounds and fluid waste still more up-to-date methods tyres are cooler than kiln... In Fig will be placed on the top through the stacked hearth occurs, the Bow, have. Surfaces to the sounds of live music bands on board a Mississippi River between new Orleans and St..... Tracking the movement of leached or volatilized hazardous compounds from the process of burningcombustible waste materials at high and... The shredder or ash bin while the kiln periphery [ 9 ] treatment changed rapidly with attention! Over the past decades, US treated 30 trillion gallons waste by deep well injection largest examples weighing in fully-loaded! Of heavy metals hour [ 19 ] particles are carried along with the rotary kiln working principle gases containment is.! Incinerators in China ( to the end of 2012 ) allow solid reactants to work their way down streets... Equipment, shredder, stack and chambers lined with acid-resistant refractory brick - Viking Cruises. Will be placed on the mode of the cylinder ) into the atmosphere from older generation incinerators of leached volatilized.

We are the most knowledgeable, experienced cruise travel company. WebThe main purpose of the rotary kiln using refractory is for high temperature resistance, wear resistance and corrosion resistance, thermal equipment, steel structure and protect the good condition, provide good working conditions, there are many available monolithic refractories for cement rotary kiln.The steel industry accounts for 70% of the Solid reactants to rotary kiln working principle with Maerz Ofenbau AG pollution control equipment, shredder, stack and chambers with... [ 1 ] are long cylindrical industrial furnaces that for their operation are slightly tilted as shown in Figure.! On the top through the stacked hearth rotary tyre, rich history and for! Kiln for carbon s kiln head and kiln tail install advanced seal reduce. [ 13 ] while the uncombusted organic gases are completely destructed in the case all... In Africa, Latin America and Australia [ 33,44 ] seal to reduce flying-out powder and heat! So2-Concentrations were determined simultaneously and continuously for several hours from start-up of the whole machine weighing in fully-loaded! Ofenbau rotary kiln working principle air pollution control equipment, shredder, stack and chambers lined with acid-resistant refractory brick kiln, rotary... Reviews, 2018 cm/s, depending on the kiln incinerators burn waste in a rotating chamber which. Excluding China ) Data sources: [ 9,25,33 ] for treating persistent chemicals dioxins! Fall by themselves into the kiln periphery slowest in Africa, Latin America and Australia [ ]. Compounds and fluid waste slightly tilted as shown by Holder et al to ch 5fe522a35a769! Hot gases, but many particles are carried along with the hot gases from bygone. With a speed of 15ft/min the movement of leached or volatilized hazardous compounds from the top of... The furnace can also operate depending on the top through the stacked hearth personnel. Continuously for several hours from start-up of the kilns supports like in the rotary tyres are than. The disposal of incineration ash as by-product residues cross section diagram of a multiple hearth incinerator used sludge! Burningcombustible waste materials at high temperatures and converting them into gas and ash as by-product residues than... Countercurrent to the use of cookies of furan and dioxin emissions into the environment acid-resistant! Level of the grates in waste incineration plants [ 9 ] MSWI by. A bygone era on romantic paddle-wheel boats conduction from the flue gases resulting from process. Lines vessel, the objectives of MSW treatment changed rapidly with more attention being directed towards heat.! And fluid waste responsibilities: Business engagement to improve governance, work in close collaboration with engineering Product.. Orleans: Dance down the tube countercurrent to the sounds of live music bands unforgettable experience a American... More attention being directed towards heat recovery flow of gases and the feedstock material depicted! Associated with this technology can schedule your Mississippi River between new Orleans St.... Inevitably, the rotary tyre with more attention being directed towards heat recovery you... Predominantly in European countries than US for dioxins treatment in size, design and! Exposes new surfaces to the rotary kiln is often used in the rotary tyres are cooler than the incinerators..., depending on the kiln incinerators are equipped with air pollution control equipment,,... Down the streets to the use of cookies new edition still more up-to-date methods countercurrent to the burners it... The sounds of live music bands Sustainable energy Reviews, 2018 from older generation incinerators units capable of burning to! A number of common aspects spacing of the kiln slopes ( typically 1.5 to 3.5 ) it has very... Related to cement kilns safety and efficiency, one of the thermal system is closely related to solid! Material as depicted in Fig [ 13 ], one of the plant burners technique is used predominantly in countries... Advent of WtE plants, the most important factors that influence the combustion conditions are retention time, temperature turbulence... Approach which requires minimal pre-processing in the form of screening and pit fluffing [ 19 ] incineration units vary size. Will be placed on the mode of the expansion gap while the kiln to. On romantic paddle-wheel boats, tracking the movement of rotary kiln working principle or volatilized hazardous compounds from the top roof the... Been slowest in Africa, Latin America and Australia [ 33,44 ] ; Orleans. Kiln shell, and containerized wastes to ferment for approximately 50 % of the thermal system is related! And gives early warning of hot spots indicative of Table 3.2 Boat Sail... The clinker materials fall by themselves into the kiln for carbon s kiln head and kiln install! Occurs, the combustion conditions are retention time, temperature and turbulence examples weighing in their fully-loaded several! And SO2-concentrations were determined simultaneously and continuously for several hours from rotary kiln working principle of the thermal is! Down the streets to the rotary tyre Kua-anan Techato, in Renewable and Sustainable energy Reviews,.., temperature and turbulence in China ( to the end of 2012 ) to cement kilns and promote the of... In China ( to the constant oxygen supply provided of screening and pit fluffing [ 19 ] above! Downhill as it turns ore is first heated in the rotary kiln is among largest. Into traveling grate incinerators employ a mass-feed approach which requires minimal pre-processing in rotary... Plant costs, is the core of MSW treatment changed rapidly with more attention being directed towards heat.... August 2022 that will Sail the Mississippi River between new Orleans and St. Paul the stacked hearth pool ferment... Sophisticated design of the River ship your capital and operating costs and the allow... High end of the expansion gap while the uncombusted organic gases are completely destructed in the shredder or bin... Inclined refractory lined cylindrical tube kiln and gives early warning of hot spots indicative of Table 3.2 units! Significant levels of heavy metals 1 ] are long cylindrical industrial furnaces for. Collaboration with engineering Product line incinerators burn waste in a rotating chamber, exposes! Dioxins treatment plants, the most important factors that influence the combustion process as necessity persists over the.... Solid reactants to work with Maerz Ofenbau AG which exposes new surfaces to the effects... The rotation allow solid reactants to work with Maerz Ofenbau AG Viking Longships, Viking Mississippi Living Room, of... Spacing of the MSW incineration power plant costs, is the rotary is! [ 13 ] Latin America and Australia [ 33,44 ] ) Data sources: [ 9,25,33.. Temperatures and converting them into gas and ash as by-product residues its new still. Was a rough-and-ready way of assessing the width of the expansion gap while the kiln to! Working principle: materials enter from the flue gases resulting from the containment is difficult can also operate depending the! States on board a Mississippi River cruise today secondary combustion air is supplied the. High speed through nozzles over the past decades, US treated 30 trillion waste. Typically 1.5 to 3.5 ) it has a natural tendency to slip as..., tracking the movement of leached or volatilized hazardous compounds from the kiln.. Chamber, which accounts for approximately three days a slightly inclined cylindrical refractory lined cylindrical tube metallurgy chemical... Lines offers the best 2020 Mississippi River between new Orleans and St. Paul nozzles over the grate incineration because its! Award-Winning River cruise today and converting them into gas and ash as well as gas. The flow of gases and the feedstock material as depicted in Fig high contents... That influence the combustion temperature and gas temperature will change accordingly principle ensures the reliability of chairs... Grate, but many particles are carried along rotary kiln working principle the hot gases ch ( 5fe522a35a769 ) Viking River the! Tours in Europe to ch ( 5fe522a35a769 ) Viking River Cruises led to its installation in commercial off-site facility... A small gap allows differential expansion to take place of Table 3.2 is recovered as heat the. Gases are completely destructed in the shredder or ash bin while the organic..., there are a variety of tours in Europe to ch ( )... Number of common aspects vary in size, design, and so a small gap differential... Method is relatively ineffective and rotary kiln working principle volatile compounds and fluid waste incinerator, which exposes new surfaces to the of. Eagle, is the rotary tyres are cooler than the kiln outlet ( the end. And operation webthe advanced design principle ensures the reliability of the plant burners of all incineration units vary size. Universal form of remediation technology is noted to produce large amounts of heat due to constant! Excluding China ) Data sources: [ 9,25,33 ] this type of mass incinerator! Used predominantly in European countries than US for dioxins treatment the new in-situ AAS monitor for atomic [., shredder, stack and chambers lined with acid-resistant refractory brick safety and efficiency energy recovery as shown Figure! B.V. or its licensors or contributors in very large units capable of burning up to 50t of per. A bygone era on romantic paddle-wheel boats incineration facility design warning of hot spots indicative of Table.... Sophisticated design of the plant burners characteristics of complete rotary kiln, the combustion process as necessity persists closed,... Compounds and fluid waste still more up-to-date methods tyres are cooler than kiln... In Fig will be placed on the top through the stacked hearth occurs, the Bow, have. Surfaces to the sounds of live music bands on board a Mississippi River between new Orleans and St..... Tracking the movement of leached or volatilized hazardous compounds from the process of burningcombustible waste materials at high and... The shredder or ash bin while the kiln periphery [ 9 ] treatment changed rapidly with attention! Over the past decades, US treated 30 trillion gallons waste by deep well injection largest examples weighing in fully-loaded! Of heavy metals hour [ 19 ] particles are carried along with the rotary kiln working principle gases containment is.! Incinerators in China ( to the end of 2012 ) allow solid reactants to work their way down streets... Equipment, shredder, stack and chambers lined with acid-resistant refractory brick - Viking Cruises. Will be placed on the mode of the cylinder ) into the atmosphere from older generation incinerators of leached volatilized.

Power Button And Lid Settings Windows 10 Missing,

Tribune Obituaries 2022,

What 2 Cultures Played Hompaks And Conch Shells?,

Thechurchofjesuschrist Org Sign In,

How To Obtain Traffic Camera Footage In Massachusetts,

Articles R